“NUIG has the expertise and the equipment to develop this technology much faster and more efficiently that we would be able to do in-house.”

Dr. Brendan Boland, Co-founder, Loci Orthodopaedics

Overview:

Case study: Loci Orthopaedics

‘Thumbs, shoulders, knees and toes, knees and toes’ is (almost) what the song says, and it more or less sums up the orthopaedic space within which NUIG spin-out company Loci Orthopaedics is operating. Co-founded in 2017 by Dr. Brendan Boland (CEO) and Gerry Clarke (CTO), the multi-award-winning company is targeting the fastest growing area in orthopaedic medicine – orthopaedic extremities.

“In 2013, I became a fellow in the BioInnovate programme, where I met Gerry. We identified the unmet clinical need of treating upper limb arthritic conditions. That led to the establishment of Loci Orthopaedics and the development of our primary product, the InDx implant, which can mimic the complex motions of the thumb base joint,” explains Boland.

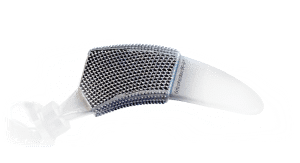

The company then began work on a second product, a shoulder implant. Recognising that achieving good primary fixation is problematic for patients with poor bone stock, it licensed OsteoAnchor – technology that had been developed by Dr. Noel Harrison of the School of Engineering at NUIG, who is a leader in the field of additive manufacturing (3D printing).

“The OsteoAnchor technology allows implants to better adhere to the bone by providing a roughened surface that the person’s own bone can grow into….”

We felt that this technology fitted our focus but we needed to optimise its effectiveness and de-risk it to give us the confidence to invest in developing new products using it. Having benefitted in the past from excellent support from Enterprise Ireland, we turned to its Innovation Partnership Programme for help,” says Boland.”

The power of partnership

The Innovation Partnership Programme enables companies to access expertise within universities and research institutes and covers up to 80% of the cost of a research project. With NUIG’s recently opened Advanced Manufacturing Lab (developed by Dr. Harrison) located just metres from Loci Orthopaedics, it made sense to ask Harrison’s team to lead the Innovation Partnership Programme project.

“They have the expertise and the equipment to develop the OsteoAnchor technology much faster and more efficiently than we would be able to do in-house,” says Boland.

Dr. Eimear O’Hara is the technical lead and project manager. “It’s an ambitious six-month project,” she says. “We’re taking a concept implant and doing the design, prototyping and mechanical testing here in the lab, where we have extensive 3D printing capability. The deliverable will be a metal 3D printed shoulder implant.”

The Innovation Partnership Programme will deliver benefits to both the company and the university.

“As well as de-risking the technology, the Innovation Partnership Programme validates it to external parties because the project goes through commercial assessment,” says Boland. “And there’s the potential for the Innovation Partnership Programme collaboration to lead to further innovation.”

From NUIG’s perspective it’s the chance to engage with industry to get insights into real world applications of 3D printing and to demonstrate the capability of its 3D metal printer.

“This kind of collaboration also informs the content of my lectures, helping to keep Mechanical Engineering students up to date about additive manufacturing processes, materials and product design,” says Harrison.

“It’s the first time we’ve used the 3D metal printer for an industry-based project. We’re hoping that many more companies will be interested in working with us on using our suite of 3D printers, not just in the medtech space but across all manufacturing,” he adds.

The journey to market

With the combined value of the markets for its shoulder and thumb base implants currently sitting at around US $2 billion, the outcome of the Innovation Partnership Programme project will be an important milestone for Loci Orthopaedics, enabling it to take the next steps on its journey to market.

“Our primary market is the US and this year we’ll be making a regulatory submission relating to our InDx product in advance of commercialisation in the US in 2021. We’re aiming to do our first clinical trial of InDx in Europe in June and are anticipating commercialisation in the EU in 2022,” says Boland.

The same process will apply to the shoulder implant, following about two years behind.

“Meanwhile we’ll have an active in-house innovation and R&D programme. We’ve already secured patents, have four more filed and 16 more in development. Over the next five years we’re hoping to roll out a whole suite of products.”says Boland.

Until the products hit the market the company will run lean, maintaining just three staff and using manufacturing and processing partners. Financing currently comes from €6 million secured from seed funding, grants and prizes.

The Innovation Partnership Programme experience

Loci Orthopaedics received a grant of €85,000 from the Innovation Partnership Programme and contributed €16,000 to the project.

“For a modest sum of money, we are getting a great deal of work done, a good bang for your buck, as they say. Moreover, applying for the Innovation Partnership Programme grant is relatively straightforward and Enterprise Ireland ensures that the IPP agreement clearly sets out what is expected from each party and what each will get out of it, for example, in the area of intellectual property or how new innovations resulting from the project will be handled. This project is enabling us to add to our R&D pipeline and increase our product portfolio,” says Boland.

Dr. Harrison encourages companies to think big when considering the Innovation Partnership Programme: “A company may have a technical problem that they need help on but they’re thinking about it in terms of their bandwidth. Through the Innovation Partnership Programme, they can get access to a university’s massive suite of equipment, expert personnel and state-of-the-art facilities.”